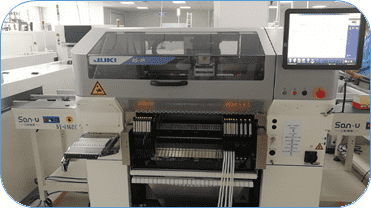

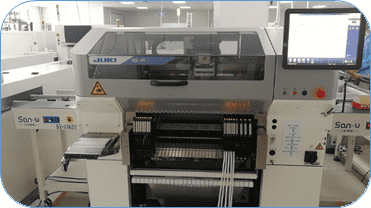

The Mounter JUKI RS-1 is a high-speed, modular SMT placement machine designed for precision assembly of components ranging from 01005 chips to large 45×45 mm packages. With a mounting speed of 42,000 CPH, it integrates Smart Balance Technology to optimize line efficiency and reduce downtime. Its RF Feeder system ensures stable component feeding, while the adaptive head unit dynamically adjusts recognition and placement parameters for diverse PCB layouts. Ideal for automotive, consumer electronics, and IoT manufacturing, the RS-1 supports Industry 4.0 workflows with real-time diagnostics and maintenance alerts, backed by detailed maintenance guides for streamlined operations. Compliant with IPC-9851 and ISO 9001 standards, it combines flexibility, speed, and reliability for high-mix, high-volume production.