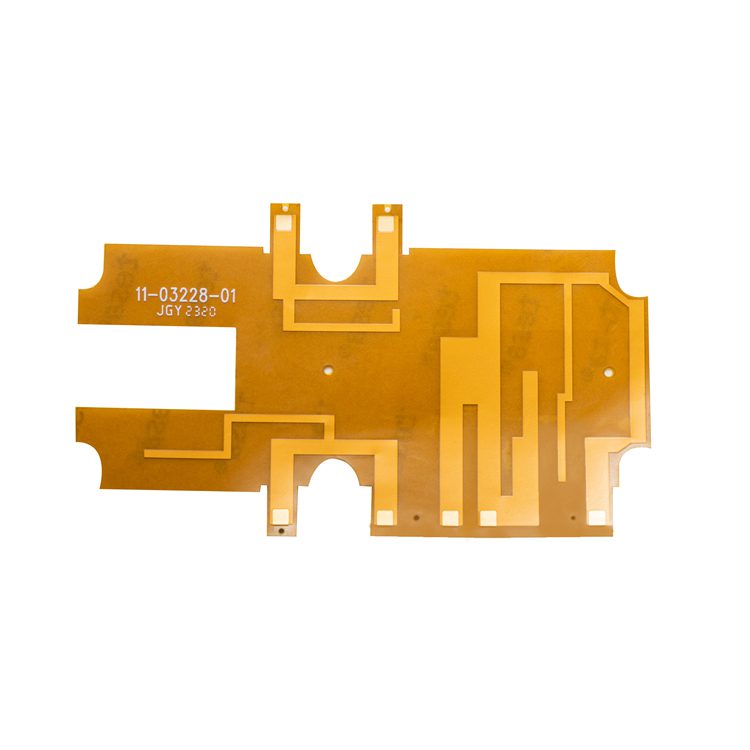

With the development of electronic devices towards smaller and thinner sizes, flexible circuit boards have become the preferred choice for many high-tech products due to their unique bendability and spatial adaptability. The single-sided, double-sided, and multi-layer design of FPC not only optimizes space utilization, but also enhances the flexibility and complexity of circuit design.

Single, double-sided, and multi-layer design of flexible circuit boards

1. Advantages of single-sided and double-sided FPC design

Single and double-sided FPC design is favored for its simplicity and cost-effectiveness. In single-sided design, all electronic components are mounted on one side of the FPC, which simplifies the manufacturing process and reduces costs. The double-sided design provides more space to arrange components, making it suitable for applications that require more connection points.

2. Multi layer FPC design: dual improvement of space and performance

Multilayer FPC greatly increases design density by arranging circuits on multiple levels, providing possibilities for the layout of high-density components. This design not only saves valuable space, but also improves the stability and anti-interference ability of signal transmission.

3. Balance between flexibility and reliability

Although the flexibility of FPC brings convenience in design, it also poses challenges to the reliability and durability of materials. The design of multi-layer FPC needs to consider the bending life of materials and their physical stability in repeated use.

4. Diversification of application scenarios

From connecting the display screen of smartphones to the circuit layout of wearable devices, to the complex wiring in automotive electronics, the single-sided, double-sided, and multi-layer design of FPC meets diverse application needs. Each design choice needs to be customized according to specific application scenarios and performance requirements.

5. Challenges in Design and Manufacturing

Although FPC provides design flexibility, its manufacturing process is also more complex, requiring precise process control and high-quality materials. When designing, factors such as signal integrity, thermal management, and electromagnetic compatibility also need to be considered.

The single-sided, double-sided, and multi-layer design of flexible circuit boards is the key to modern electronic device design. Through careful design and manufacturing, FPC can meet the growing demand for miniaturization, flexibility, and high performance.