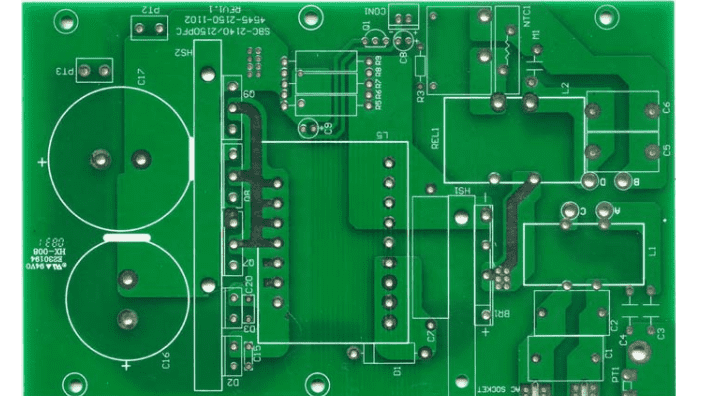

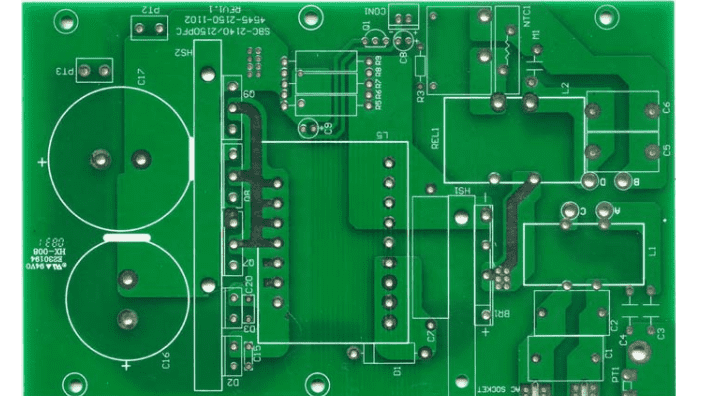

Printed Circuit Board (PCB) plays a very important role in the electronics industry, and its quality directly affects the stability and performance of electronic products. In the PCB manufacturing process, green plug holes and voids are a very easily overlooked but crucial issue.

Firstly, let’s understand the function of the PCB green oil plug hole. PCB green oil plug hole refers to the process of plating copper, tin, or directly applying green oil into the hole to prevent solder mask coating from entering the hole during solder mask coating on the PCB board.

The insufficient fullness of the green plug hole may lead to the following problems.

Firstly, it can lead to uneven solder mask coating. When the PCB green oil plug hole is not full enough, it can cause uneven thickness of solder mask coating around the hole, and even some parts have no solder mask coating at all. This will result in weak welding during the welding process, thereby affecting the reliability of the circuit connection.

Secondly, it will lead to a decrease in the insulation performance of the circuit board. One of the functions of the green oil plug hole is to prevent solder mask coating from entering the hole and ensure the insulation performance inside the hole. When the green oil plug hole is not full, this cannot be guaranteed, resulting in a decrease in the overall insulation performance of the PCB board, and even affecting the safety of the entire electronic product.

Thirdly, it will lead to a decrease in welding quality. In PCB manufacturing, welding processes are usually carried out, and green plug holes and voids can greatly reduce the quality of welding. For example, the solder paste capacity of the solder pad will be affected, and problems such as incomplete solder paste and solder paste shrinkage are prone to occur during the soldering process, resulting in unstable soldering quality. And this quality issue can easily cause problems such as poor circuit contact and loose connections during use. And these issues will seriously affect the normal operation of electronic products.

Of course, to solve the problem of green oil plug holes, we need to start from the source first. In the PCB manufacturing process, manufacturers need to strictly control the processing technology of green oil plug holes to ensure the qualified fullness of the plug holes. Secondly, in the final process of PCB manufacturing, strict quality inspection and testing are required to ensure that the quality of the green plug holes meets the requirements.

In addition, choosing a PCB manufacturer with a good reputation and rich experience is also crucial. In short, the problem caused by insufficient fullness of Pcb green oil plug holes is very serious, which not only affects the reliability and performance of electronic products, but also brings incalculable losses to manufacturers. Therefore, all PCB manufacturing companies and related practitioners should attach great importance to this issue and take effective measures to solve it.