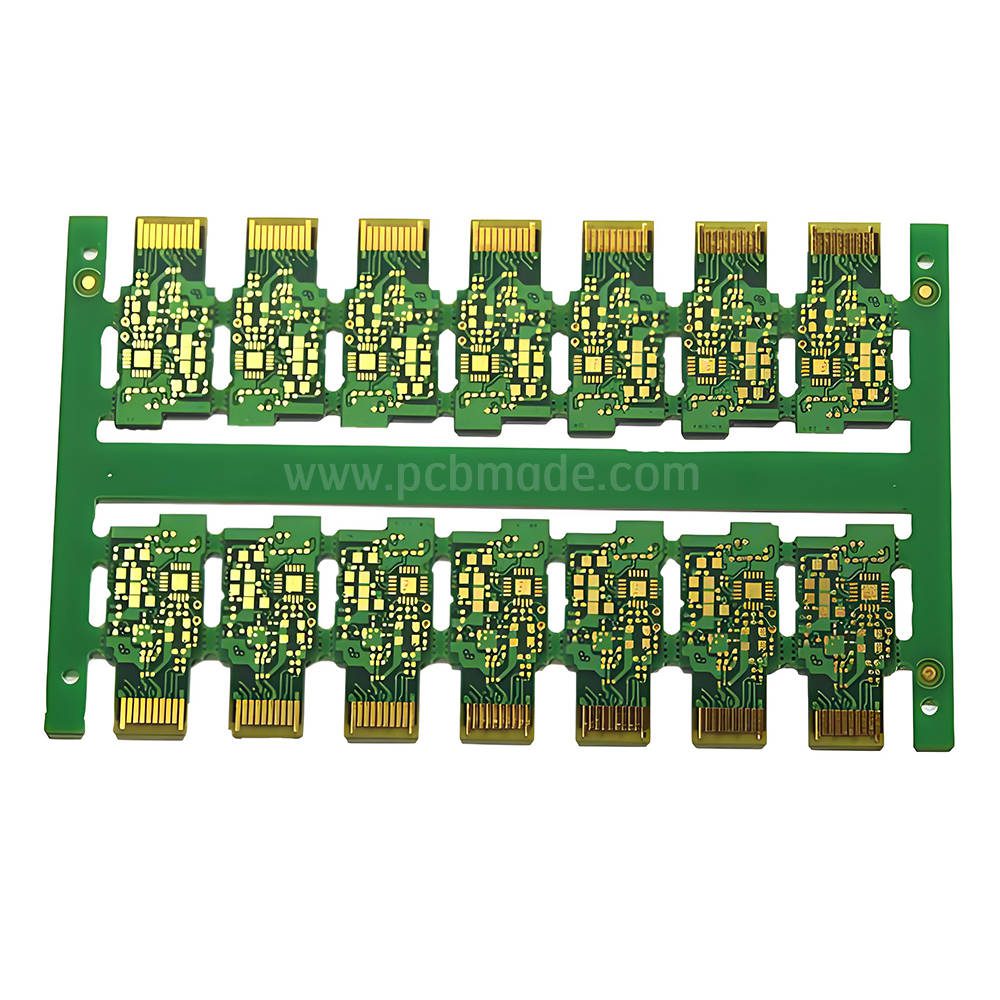

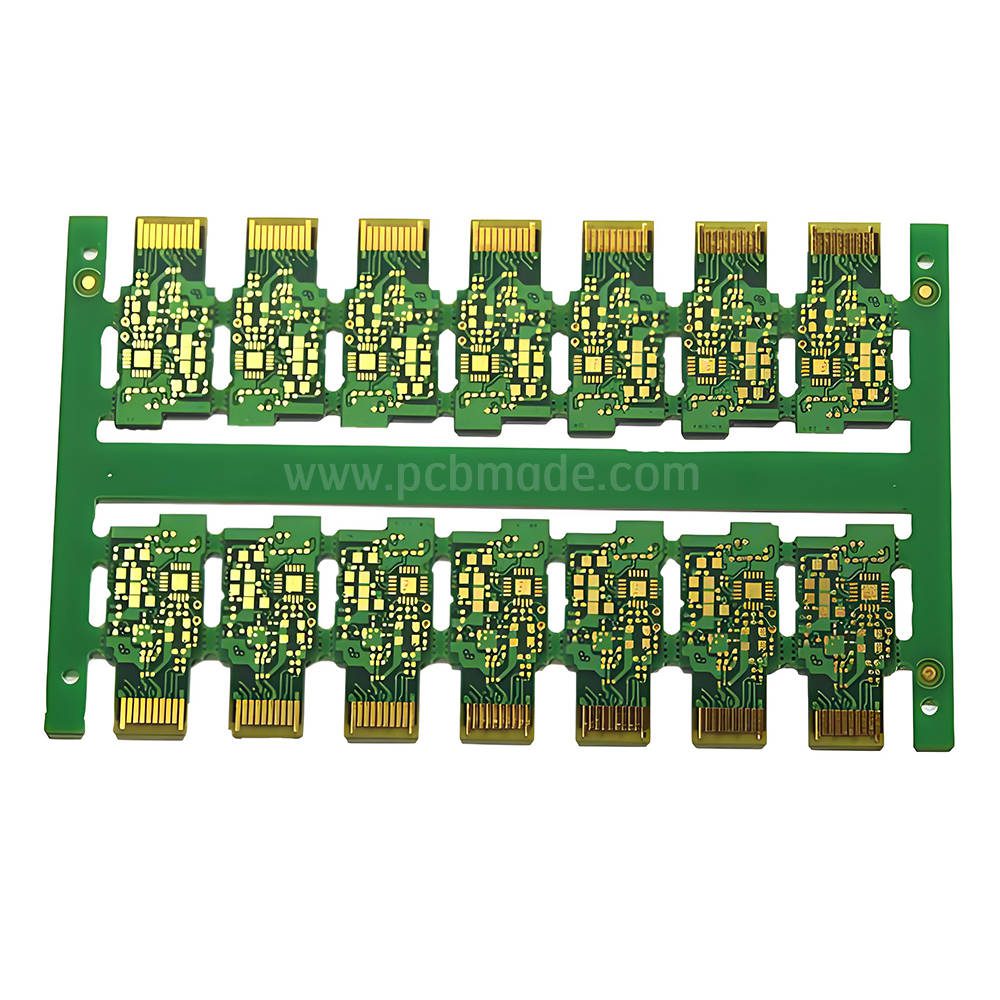

PCB gold fingers are electrical contacts on printed circuit boards, and their special process requirements have a significant impact on the reliability and stability of electronic products. Today, the Huihe editor will share the essential skills and experience required for PCB gold finger processing, helping you easily master PCB gold finger processing.

1. Material selection

The selection of materials is crucial in the manufacturing process of PCB gold fingers. Gold fingers typically use high-quality materials such as pure gold, gold alloys, or gold electroplating to ensure the stability and reliability of current conduction. At the same time, the selection of materials should also consider corrosion resistance and wear resistance to increase their service life.

2. Process control

The processing technology of gold fingers needs to be strictly controlled, including electroplating technology, cutting technology, and arrangement method. In the electroplating process, attention should be paid to controlling the electroplating thickness to ensure consistency between resistance and conductivity. The cutting process should ensure the flatness and accuracy of the cutting, and avoid affecting the use of the golden finger. The arrangement of gold fingers should meet the design requirements of the product to ensure the reliability of electrical contact.

3. Design optimization

In PCB design, the layout and structure of the gold fingers should be optimized. The layout of golden fingers should avoid crossing and overlapping as much as possible to reduce interference in current conduction. The design of the structure should take into account the effects of mechanical and thermal stresses to increase the strength and stability of the golden finger.

4. Testing and Inspection

In order to ensure the quality of the margin finger, strict testing and inspection are required. Common testing methods include visual inspection, dimensional measurement, and electrical performance testing. Visual inspection is used to check the surface defects and damage of gold fingers; Dimensional measurement is used to verify the accuracy of the size of the gold finger; Electrical performance testing is used to test the conductivity and ability of gold fingers.

5. Maintenance and upkeep

The maintenance and upkeep of golden fingers are crucial for extending their lifespan and maintaining stability. Regularly clean the dust and impurities on the surface of the golden finger to avoid corrosion and accumulation that may cause an increase in resistance. Meanwhile, during use and storage, attention should be paid to avoiding scratching and collision of the golden fingers to maintain their integrity.

Mastering the requirements of PCB gold finger technology requires accumulating experience and skills. Choosing appropriate materials, strictly controlling processes, optimizing designs, conducting effective testing, and performing proper maintenance are all key factors in ensuring the quality of PCB gold fingers.