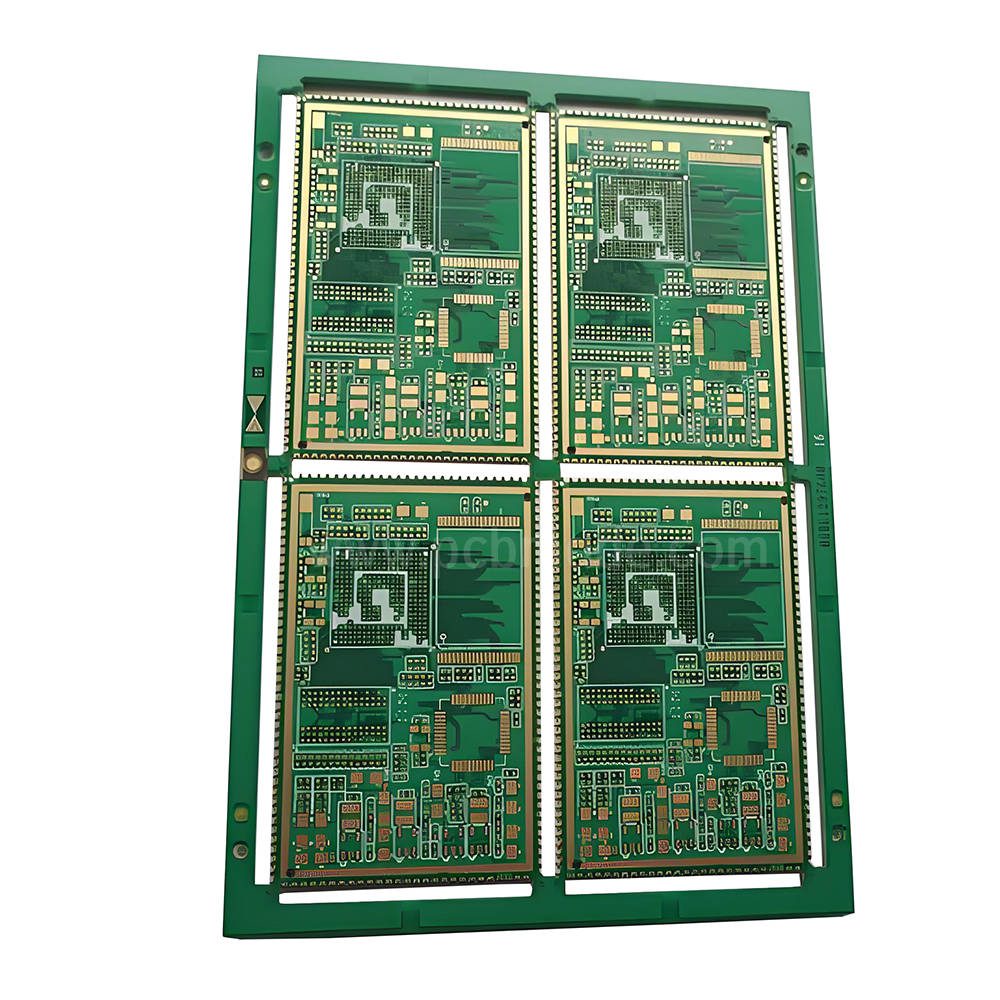

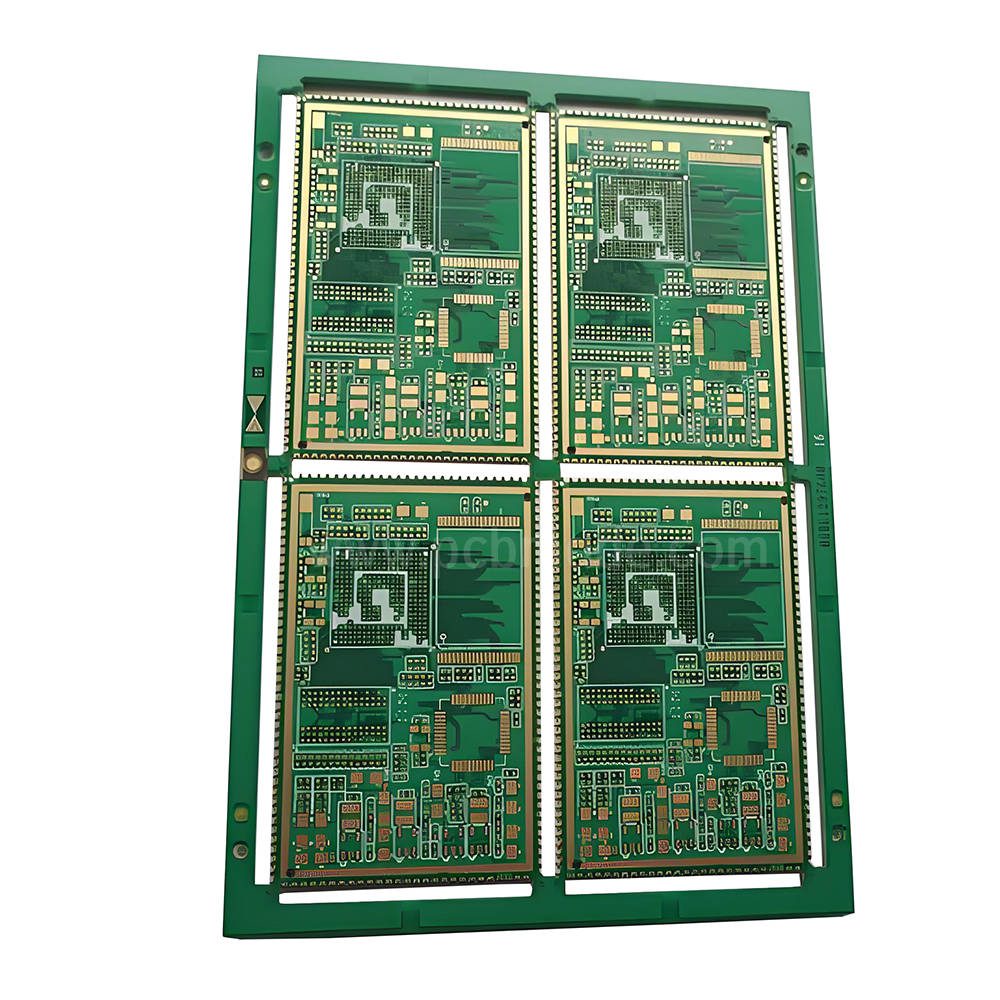

With the continuous development of electronic technology, PCB has become an indispensable and important component in modern electronic devices. Adhesive plays a crucial role in accurately connecting various components on a circuit board. So, what exactly is the glue on the circuit board?

The adhesives used on circuit boards are mainly divided into two types: conductive adhesives and non-conductive adhesives. Conductive adhesive is generally composed of conductive particles, polymer matrix, and other additives, and has good conductivity. It can not only bond various materials, but also provide a transmission path for electronic signals. Non conductive adhesive mainly plays a role in fixing and insulation, which can protect the components on the circuit board from external environmental interference.

When choosing glue, the first step is to determine it based on the specific application scenario of the circuit board. For example, for circuit boards used in high-temperature environments, it is necessary to choose adhesives that can withstand high temperatures. Secondly, consider the performance requirements of the adhesive, such as bonding strength, chemical resistance, heat resistance, etc. In addition, it is necessary to consider the construction process requirements of the adhesive, such as curing time and curing temperature.

For conductive adhesives, their conductivity is one of the most important indicators. Normally, the conductivity of conductive adhesive is determined by the concentration and size of conductive particles. Higher concentrations and smaller sizes of conductive particles can provide better conductivity. In addition, the durability and stability of conductive adhesive are also factors that need to be considered. Because circuit boards are subject to environmental factors such as temperature and humidity changes during use, adhesives need to have high durability and stability.

For non-conductive adhesives, the main indicators to consider are their adhesive strength and insulation performance. The strength of the adhesive directly affects the quality of the connection between the components and the circuit board, while the insulation performance is related to the safety and reliability of the circuit board. Therefore, when choosing non-conductive adhesive, it is necessary to focus on these two indicators.

In addition to conductive and non-conductive adhesives, there is a special type of adhesive widely used in the production of circuit boards, which is epoxy resin adhesive. Epoxy resin adhesive has excellent bonding strength and electrical insulation properties, making it very suitable for the production of circuit boards. At the same time, it also has the characteristics of high temperature resistance and chemical corrosion resistance, and has been widely used in the production of electronic devices.

In short, there are various types of adhesives on circuit boards, and different adhesives have different properties and applications. When choosing glue, it is necessary to comprehensively consider factors such as conductivity, adhesive strength, temperature resistance, and chemical resistance based on the specific application scenarios and requirements of the circuit board. Only by selecting the appropriate adhesive can the quality and performance of the circuit board be ensured, making electronic devices more stable and reliable.